Tekniken

CO2-Snow Jet Cleaning

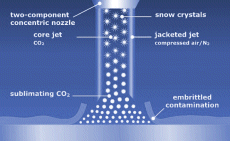

CO2 Snow-Jet Cleaning systems use solid CO2 ice crystals as a jet medium. With its combination of mechanical, thermal and chemical properties, CO2 snow is able to gently detach and remove a whole variety of surface contamination. Developed at the Fraunhofer IPA in Stuttgart, Germany, the sublimation-impulse technique is the most efficient process to date for cleaning with CO2 snow worldwide.

As the liquid CO2 expands at the nozzle outlet, CO2 snow is formed which is accelerated to supersonic speed using a compressed-air jacketed jet and blasted onto the surface to be cleaned.

CO2 as a Cleaning Agent

Supersonic impulse while maintaining low CO2 consumption

As compressed air is used to accelerate the CO2 snow crystals, CO2 consumption is considerably lower than in one-component nozzle systems – and that’s with an increased performance at the same time.

- Embrittlement of the contamination through rapid cooling

- Detachment due to the transmitted forces of pressure and shearing

- Dissolving of adsorption bonds (solvent)

- Rinsing (increase in volume of approx. 500x during sublimation)

- Dry cleaning process

- Non-abrasivev

- Solvent free

- Environmentally-friendly and non-toxic

- Cleaning is material non-dependent

- Residue-free cleaning

- Reducing costs

- Improves product quality and process efficiency