Phasa-applikationer inom el-industrin

|

|

PHASA-processen är idealisk för montering av kretskort och ger en permanent, långsiktig säker fixering utan att skada kortets yta.

Upp till 300 infästningar per maskincykel är möjliga. |

|

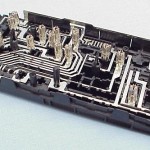

Denna säkringsdosa har flera fixeringspunkter som använder standardmaskinen PHASA 20/40 för att beskära metallarbetet och känna av kretskontinuiteten i en komplett operation.

. |

|

En kontaktbrytare i stora volymer för hushållsbruk har djupt hålade stakar som bearbetas av PHASA. Detta ger inte bara en tät och säker fixering utan förhindrar manipulering och ogiltiga garantianspråk. |

|

Denna interna komponent för en myntautomat har två 0,6 mm. nitar som formas för att behålla flexi-kretsen. Det är inte bara en ömtålig enhet, den är byggd för att tåla konstant användning och ibland fungera i tuffa miljöer.

|

|

Detta hölje med RFI-metallinsats för nätverkshubbar har grupper av insatser som bearbetas i ett pass. PHASA-fixeringen förblir säker vid användning under olika klimatförändringar. |

|

Att fästa ett glasfönster i en plastram för denna mikrovågsdörr uppnås genom att forma ett antal ribbor i en riktning.

Det är viktigt att glaset hålls kvar på ett säkert och läckagesäkert sätt och ger den styvhet som krävs även efter upprepade stängningar |

|

Med hjälp av en specialbyggd flödesledningsmaskin har denna högvolymsäkerhetskritiska brandpunktsplatta en mikrobrytare på plats. Lika viktigt som hög kapacitet är en fläckfri A-yta. |

|

Sony-datorskärmsskydd bearbetas med en standard PHASA 40/40-maskin som säkrar kontrollknappsträden. Noggrann processtyrning och konsolideringstryck är avgörande för att uppnå rätt mellanrum runt varje knapp och öppning. |

|

Att fästa mässingskontakter i denna ändkåpa uppnås genom att omforma plasten som en rollover för att behålla kontakten

|