Friktion

Friktionsprodukter

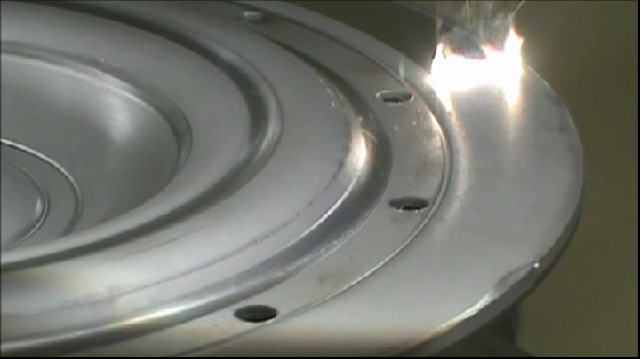

Automatiserad laserytberedning

Perfekt för kopplingskomponenter eller bromsbelägg

CleanLasers system är idealiska för att rengöra och skapa en mikroråhet i ett steg. Lasern kan ta bort föroreningar och oxider samtidigt som den skapar en grov yta.

Denna funktion används inom industrin för drivlinor, där lasern förbereder kopplingsplattor innan friktionsmaterialet binds till metallbärarplattan.

Det är en stor fördel med laserrengöringen att lasern inte tillför slipmedel till plattan (som aluminiumoxid från den konventionella blästringsprocessen).

Laserrengöring av bromsbeläggets bakplatta möjliggör ett snabbt och mycket kostnadseffektivt sätt att avlägsna föroreningar på bakplattan före beläggningsprocessen.

Anbränning eller andra produktionsprocesser med värmepåverkan på bromsbeläggets bakplatta av metall skapar oxidprodukter som måste avlägsnas innan plattorna beläggs. Laserrengöring av bromsbelägg är det överlägsna alternativet till konventionella ytbehandlingsmetoder, d.v.s. sandblästring, för att rengöra bakplattans yta.