CFRP-reparation

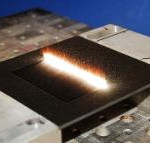

Laserbaserad reparation för Cfrp-komponenter

Beröringsfri bearbetning och förbehandling för limning

En ny laserbaserad metod möjliggör effektiv skikt för skikt-borttagning och ytförbehandling av CFRP för strukturell ytbehandlingsreparation, t.ex. för limning av clips och klämmor eller strukturell stegvis limning. De mekaniska hållfasthetsegenskaperna som realiseras i processen tillåter överlägset strukturellt bindningsbeteende, t.ex. för flygindustrin.

Fördelar:

- Utmärkt rengörings- och ablationsresultat och snabbhet

- Förbättrad vidhäftning

- Innovativ robust diodpumpad laserteknik

- Mycket låga driftskostnader (vanligtvis 1-3 €/h)

- Ingen gasförbrukning, ”Plug & Go”-teknik

- Flexibel applikation tack vare bärbar teknik

- Underhållsfri teknik

- Hög tillförlitlighet, ingen ”mänskligt fel”-faktor, potential för automatisering och certifiering

EKOLOGISKA EFFEKTER

- Inga slipmedel, inga kemikalier

- Inget avfall förutom borttagna CFAP-skikt