Fordon

Phasa-applikationer inom bilindustrin |

|

|

Ford Focus bildörrar bearbetas (en var tionde sekund) med PHASA Rotary-maskiner i Spanien och linjära maskiner i Mexiko. Bearbetningsenheter gjorda av träflis eller plastsubstrat som ofta inkluderar avkänning och streckkodsläsning utgör en viktig del av Phasas verksamhet.

|

|

|

Denna säkerhetskritiska enhet för krockkuddar är väl lämpad för PHASA-processen, med olika insatsprofiler som behandlas samtidigt, vilket ger en säkerhet och skyddsfixering som fungerar bra i ”pull off”-tester och extrema klimatförhållanden.

|

|

|

Phasa-maskiner används flitigt i tillverkningen av dessa ”fly by wire” gaspedaler. Phasa har nu över 20 standardmaskiner i USA som tillverkar dessa produkter, där de små torkarkontakterna, den keramiska insatsplattan och topplocket sätts fast.

|

|

|

De nya BMW mini ryggstöden har kartnätet och mattremsan satsade med Phasa IV30/30-maskinen. Med målade ytor var det extremt viktigt att undvika märken på ”A”-ytan, denna inverterade maskin övervann alla potentiella problem samtidigt som den gav enkel operatörsbelastning och komponentavkänning.

|

|

|

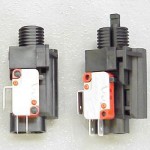

Denna pneumatiska sätesjusteringsomkopplare bearbetas med standardmaskinen PHASA 10/30 (med dubbla avtrycksverktyg). Den ena delen har en mikrobrytare monterad medan den andra har en packning och en ”O”-ring som ingår för en lufttät försegling för att styra en tryckkontrollventil.

|

|

|

Ett hanteringssystem under motorhuven sätts med hjälp av ett PHASA-levererat bearbetningshuvud för inkorporering i ett kundtillhandahållet flödeslinje-pallettsystem. Monteringsmetoden valdes för dess konsekventa tillförlitliga funktion och förmågan för fästena att förbli säkra medan de används i en tuff miljö under motorhuven.

|

|

|

Denna hjulklädsel har en insättningsbricka i krom. Vid formning av denna typ av produkt är det ofta nödvändigt att maskera insatsområdet för omformning för att förhindra att kromavlagringar byggs upp. Med PHASA-processen är det möjligt att värma och omforma pålen med en tunn krombeläggning vilket sparar både tid och pengar.

|

|

|

En högkvalitativ VVS-kontrollkomponent monteras med en standard PHASA 20/40-maskin. Multiklusterstakar fixerar LED-höljen och bibehåller ett PCB till den målade fasadlisten.

|

|

|

Phasa-processen blir alltmer erkänd som det enda sanna sättet att effektivt sätta ut torkarblad med liten kontakt. Höga produktionsvolymer uppnås med bearbetning av flera komponenter med hjälp av förladdningsnest. Pålar med en diameter på 1 mm håller det ömtåliga torkarbladet på plats. Utmattning av torkarmetall och separering av glaspåfyllning elimineras. |

|