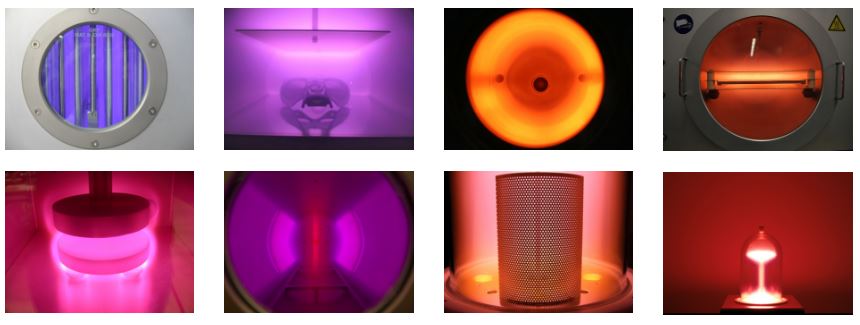

Plasmatekniken

Plasmabehandling med oändliga möjligheter

Plasmabehandling kan användas vid många olika tillfällen när du vill sammanfoga material eller för att ändra ett materials ytegenskap för olika ändamål. Med denna teknik är det möjligt att ändra praktiskt taget vilken yta som helst. Plasmatekniken erbjuder flera mångsidiga applikationer, till exempel:

- Rengör ytor på rester, oljor eller föroreningar

- Aktivering av olika material före limning, målning etc.

- Etsning och delvis borttagning av ytor

- Beläggning av delar med flera möjliga typer av skikt (PTFE-liknande, skyddsbarriärer, hydrofob, hydrofil, friktionsreducerande, etc.)

- Plasmatekniken etablerar sig inom alla industriområden och nya applikationer utvecklas ständigt.

Plasmatekniken – övertygande fördelar

Jämfört med andra metoder, som flambehandling eller användning av kemikalier för att behandla en yta, uppvisar plasmatekniken många viktiga fördelar:

- Många ytegenskaper kan erhållas uteslutande med denna procedur

- Kan användas i onlineproduktion eller drivas oberoende

- Miljövänlig process

- Oavsett geometri kan du behandla pulver, små delar, skivor, fleece, textilier, slangar, flaskor, kretskort etc.

- Tillverkade delar kommer inte att mekaniskt ändras

- Uppvärmningen av delarna är minimal

- Driftskostnaderna är mycket låga

- Mycket säkert att använda

- Processen är extremt energieffektiv

Läs mer »Plasmaeffekt

Effekten av plasma.

Läs mer »Plasmapolymerisering

För beläggning med lågtrycksplasma införs gasformiga eller flytande monomerer som polymeriserar under inverkan av plasman.

Läs mer »Ytaktivering

Plasmabehandling av en plastyta med t.ex. syre. Det bildas radikaler som leder till god vidhäftning av ytfinish och lim.

Läs mer »Jämförelse

Atmosfärsplasma eller lågtrycksplasmaFrågan är inte vilken lösning som är bra eller dålig utan vilken som passar bäst till vilken applikation.