MEF-teknik

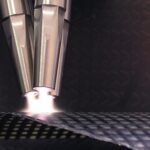

TIGRES MEF- teknik

Kall potentialfri plasma

Justerbar potentialfri atmosfärisk plasma underlättar skalbar, homogen ytaktivering före limning, tryckning, lackering och beläggning av plast, metall, papper, glas, kartong, sammansättningar av olika material och textilier.

Översikt

MEF-teknik genererar plasma av en elektrisk barriärurladdning och riktar strålen mot ytan med hjälp av tryckluft. Oavsett om ett enda munstycke för högprecisionsförbehandling, flera munstycken för bredare applikationer eller plasmamoduler för omfattande substrat – alla applikationer är möjliga med denna teknologi. Olika processgaser kan användas för att skapa speciella funktionella grupper på polymerytan.

Tekniska data MEF

| Effekt: | 200 W per munstycke |

| Kanaler: | 1-2 |

| Processgas: | Luft (annat på begäran) |

| Potential-fri: | Praktiskt taget |

| Transformer: | Intern & extern |

| EDC-teknik: | Integrerad |

| NDC2-teknik: | Kan integreras |

Skalbarhet

Tekniken kan anpassas till valfri materialbredd. Detta görs genom att rada upp så många 140 mm breda plasmamoduler som behövs för att uppnå önskad bredd.

Processintegration

Matningsledningarna till MEF-modulerna kan löpa parallellt eller vinkelrätt mot munstycket.

Modeller

Följande MEF-modeller finns:

- Enkelt munstycke

- Multiblock med 20 munstycken

Viktiga egenskaper hos MEF-teknik

- NYHET: Med EDC-tekniken, som gör att plasmaintensiteten kan justeras över hela spektrumet

- Behandlingsbredden är fullt skalbar

- Konstant övervakning av parametrar säkerställer hög processtillförlitlighet. NYHET: Nu med NDC2

- Den robusta designen kräver endast minimalt underhåll och är billig att använda

- Den aktuella driftstatusen för enheten indikeras på den inbyggda LCD-skärmen