Applikationer

Hemma i alla situationer.

CO2 snöblästring används för rengöring och förbehandling av fasta ytor. Dessutom finns det applikationer för kapning, gradning och kylning.

Tillämpningar för denna process finns inom produktion, reparation, underhåll och tjänster och kan implementeras i nästan alla branscher:

Bilindustrin,

Syntetmaterial,

Gummiindustrin,

Elektronik,

Kemisk industri,

Farmaci,

Livsmedelsindustrin,

Gjuterier,

Utskrift,

Flyg,

Transport,

Energi,

Tjänster.

CO2 snöblästringsmaskiner har en enorm potential och maximal flexibilitet. I allmänhet är maskinerna implementerade för att ta bort följande ytorenheter: partiklar, damm, fett, olja, fingeravtryck, släppmedel, black wash, tillverkningsrester, lim- och limavlagringar, polerrester, antikorrosiva medel, kylsmörjmedel, asfalt, vax, lack och tunna färgskikt, rökrester, flussmedelsavlagringar, sot, kalk samt bakterier och svampar.

Exempel på tillämpningar

1. Rengöring av verktyg och formar

- Polyuretan (släppmedel, tillverkningsrester)

- Pressgjutning, gjutformar, kärnlådor (släppmedel, black wash, tillverkningsrester)

- Galvanisering (tillverkningsrester)

- Däckformar, vulkaniseringsverktyg, ventilationsventiler (tillverkningsrester)

- PET-blåsningsformar (tillverkningsrester, avlagringar)

- Plastinsprutningsverktyg (tillverkningsrester, avlagringar)

- Tillverkningsverktyg för kompositer (släppmedel, tillverkningsrester)

2. Rengöring av maskiner och installationer

- Switchlådor

- Hydrauliska och pneumatiska komponenter

- Motorer

- Pressmaskiner och cylindrar

- Emaljering av linjer och medar

- Ugnar, transportband, containrar, tankar

- Våffeljärn, transportband

3. Rengöring av komponenter och underenheter

- Förbehandling av syntetiska komponenter före målning

- Rengöring av metallkomponenter före målning

- Avlägsna olja och fett före lim- och beläggningsprocesser

- Återställning på grund av rök- och vattenskador, speciellt elinstallationer

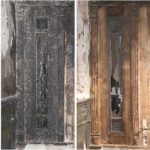

- Träsanering och sanering av brandskador

- Forma komponenter, fräsa och svarva komponenter

- Halvledare och elektroniska komponenter, linser

Film

CryoSnow - Inline cleaning of injection molds

CryoSnow - Manual cleaning injection mold

CryoSnow - CO2 pretreatment bumper paint shop

CryoSnow - Robot-guided CO2 pretreatment

CryoSnow - Pretreatment before painting with CO2 snow

CryoSnow - Clean plastic components reliably

CryoSnow - CO2 snow cleaning interior plastic parts