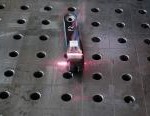

Partiell färgborttagning

Skala av lager för lager med cleanLASER

Vanligtvis tar lasern bort alla lager ner till grundmaterialet. Vid borttagning av utvalda områden måste laserpulser riktas och kontrolleras exakt. Därvid är antalet pulser per punkt avgörande. Med varje puls tas ett tunt lager bort. CleanLASER kan ta bort valda skikt lager för lager.

- cleanLASER intelligent processövervakning och kontroll kan ta bort beläggningsskikt i den exakta grad som krävs – inte mer eller inte mindre – vid behandling av skikt av enhetlig tjocklek.

- Täckfärger kan tas bort med laser för att exponera basmaterialprimer. Process ger utmärkta återbeläggningsegenskaper bekräftade av US Air Force-tester och enligt internationell flygstandard SAE 4812.

- Använder inga media, inget damm, inga kemikalier, ingen rengöring, restfri avbeläggning

- Grön teknik – ingen förorening

- Snabb installation, enkel att använda

- Handhållen laseroptik – mångsidig och ergonomiskt utformad

- Lätt att automatisera, robotoptik tillgänglig

- Strålleverans med flexibel fiberoptisk kabel upp till 150 fot lång

- Utrymmesbesparande kompakta bärbara och stationära system

- Miljövänligt – inget sekundäravfall

- Låg driftskostnad

- Minimalt underhåll

- Framgångsrik, använd i flyg-, bil- och industriapplikationer över hela världen

Applikationer

- Flygindustrin: Färgborttagning samtidigt som primern bibehålls

- Bilindustrin: vald topplackborttagning för limningsförberedelser samtidigt som primerns korrosionsbeständighet bibehålls (t.ex. limning av vindrutor)

- Korrosionsbeständighet och underhåll: Förvittrade toppbeläggningar avlägsnas noggrant innan ny lackering