Förpackningar

Plastsvetsning av förpackningar

Våra system och lösningar för försegling, svetsning, skärning och stansning av olika typer av förpackningar, såsom tuber, påsar, askar, kartong och blister med mera, bygger på högutvecklad ultraljudsteknik.

- Enkelsidig rullsömsmodul

- Ultraljudshuvud för toppförsegling KSE 250-100

- Tubförseglingsenhet TSE

- Ultraljudsförseglingssystem för slangformiga påsar

- Ultraljudssystem för blister-förpackningar, brickor, tråg och koppar

- Ultraljudsförseglingssystem för påsar

- Ultraljudssvetssystem för kartonger

- Samtidig ultraljudsskärning och försegling

- Ultraljudsskärning av livsmedel

Enkelsidig rullsömsmodul

Den enkelsidiga rullsömsmodulen från Sonotronic är särskilt lämplig för kontinuerlig försegling, svetsning och skärning utan inverkan på förpackningen. Modulen kan integreras i befintliga och nyutvecklade maskinkoncept.

En ständigt växande tillämpning för den kontinuerliga ultraljudsförseglingsmetoden från SONOTRONIC ligger i förpackningstekniken.

Här används ultraljudsrullsömsteknik främst i horisontella och vertikala rörformiga påsmaskiner. Påsar med fyra förseglade kanter kan också tillverkas genom ultraljudsvalsförsegling.

Både rullsömssonotroden och städet drivs i denna process så att det varken finns glidning eller vågbildning i filmen. Den dubbla drivningen genererar inte heller någon relativ rörelse mellan tätningshjulet och filmen.

Förutom de beprövade rullsömssonotroderna som är monterade på båda sidor har SONOTRONIC nu även utvecklat speciella ensidigt monterade rullsömssonotroder. När det gäller horisontella rörformiga påsmaskiner kan rullsömssonotrode med ensidig montering monteras direkt under den fyllda påsen.

Förutom de välkända fördelarna med ultraljudstätning, såsom tät tätning av våta ytor, optiskt tilltalande sömmar och konsekventa tätningsresultat, kännetecknas ultraljudsrullsömstekniken också av ytterligare fördelar. Vid kontinuerlig försegling överförs ingen värmestrålning till produkten, vilket är särskilt fördelaktigt när det gäller värmekänsliga produkter som choklad.

Till skillnad från termiska metoder gör ultraljudstekniken det också möjligt att använda monofilmer eftersom inget värmeokänsligt yttre skikt behöver lamineras på filmen. Dessutom kan mycket tunna polymerfilmer (15 μm) av hög kvalitet också tätas med den kontinuerliga ultraljudsmetoden, som hittills inte har varit framgångsrik med termiska tätningssystem.

FÖRDELAR:

- Kontinuerliga tätningssömmar

- Täta tätningssömmar även på produktfuktade ytor

- Ingen värmestrålning som kan skada produkten eller filmen

- Montering direkt under påsen

- Tätning av monofilmer och mycket tunna filmer (15 μm) möjlig

- Ingen glidning eller sparande av filmen

- Används i VFFS- och HFFS-maskiner och för påsar med fyra förseglade kanter

- Miljövänlig och energibesparande

TEKNISKA DATA:

| Svetsbredd [mm] | 2 – 9 |

| Max. svetskraft [N] | 250 |

| Max. varvtal [m/min] | 80 |

| Frekvens [kHz] | 35 |

| Generatorns effekt [W] | 400 |

| Max. lufttryck [bar] | 6 |

| Elektriskt anslutna belastningar på frekvensomriktaren [V] / [A] | 230 / 4 |

| Modulens mått B x H x T [mm] | 250 x 428 x 127 |

Med reservation för ändringar.

|

|

Ultraljudshuvud för toppförsegling KSE 250-100

Sonotronic erbjuder nu också en mekanisk förseglingstång med ultraljudskomponenter för fri toppförsegling av stående och plana påsar.

PNEUMATISKA FUNKTIONER

KSE 250-100 förseglingsenhet har anpassats speciellt för de mekaniska kraven på ett ultraljudsförseglingssystem. Som ett slutet all-in-system kan huvudförseglingsenheten enkelt integreras i befintliga eller nya påsfyllningssystem, vilket gör det möjligt för tillverkare av förpackningsmaskiner att konvertera till hållbar ultraljudsteknik med en komplett lösning och använda hela spektrumet av fördelar som ultraljudsteknik ger.

INGA STÖRANDE KONTURER I FÖRSEGLINGSOMRÅDET

För att uppfylla kraven på parallellitet är ultraljudssystemet och förseglingsstädet monterade på ett gemensamt kontinuerligt styrsystem. Detta styrsystem är anordnat i ett andra plan ovanför verktygen så att tätningsområdet är helt fritt från ytterligare störande konturer.

MAXIMAL FÖRSEGLINGSBREDD

På grund av tvåplanskonstruktionen är bredden på den mekaniska förseglingstången också lika med den maximala förseglingsbredden. Dessutom har tångens huvuddel utformats speciellt för att uppfylla kraven på böjhållfasthet och styrnoggrannhet hos ett ultraljudsförseglingssystem.

KUNDSPECIFIK ANPASSNING

Den maximala slaglängden, hastighetsprofilen och retentionstiden för huvudförseglingsenheten kan fritt reduceras till de specifika kraven med hjälp av servodrivningen. Själva servodrivningen är monterad i den vertikala axeln ovanför styrsystemet. Servodrivningen är kopplad till styrsystemet med hjälp av vevmekanik med automatisk tumlare i tätningsläge. Huvudtätningsenheten kan monteras kundspecifikt, till exempel över styrskenorna upptill eller nedtill, eller kan även fås med ett stativfotshus som integrerar servostyrningen.

FÖRDELAR

- Ultraljudsverktyg och förseglingstång i en enhet

- Modulära sonotroder i 20, 30 eller 35 kHz-teknik kan användas

- Gemensamt styrsystem som består av oscillerande struktur och städ

- Förseglingsstyrka som är särskilt justerbar

- Störande konturer över verktygsnivå (inte i tätningsområdet)

- Hastighetsprofil, slaglängd och retentionstid kan justeras specifikt

- Hög styrnoggrannhet tack vare återcirkulerande rullstyrning

- Höga förseglingskrafter för att undvika filmförskjutning i förseglingsprocessen

- Utrustad med kundspecifika servodrivenheter

TEKNISKA DATA

| Maximal förseglingsbredd [mm] | 250 |

| Max. slaglängd [mm] | 2 x 50 |

| Max. stängningskraft [N] | 2.000 |

| Antal cykler (cykler/min) vid max. slag | 50 |

| Max. lufttryck [bar] | 6 |

| Elektriskt anslutna laster | 3 x 400 V+N+PE 50 Hz |

| Räckvidd på städsidan [mm] | 95 |

| Räckvidd för sonotrod sida [mm] vid 35 kHz | 336 |

| Mått på förseglingstång B x H x T [mm] | 250 x 800 x 186 |

| Förseglingstång hölje BxHxT [mm] | 250 x 800 x 700 |

Med reservation för ändringar.

Tubförseglingsenhet TSE

Tubförseglingsenheten TSE förseglar ändarna av tuben säkert och tätt med ultraljud.

Tuber och komplexa laminatstrukturer kan svetsas tätt eller tätas med de individuellt anpassade verktygskonturerna på Tubförseglingsenheten. Den mycket kompakta, smala enheten kan enkelt justeras med ett modulpaket för flerbandspresslinjer.

FÖRDELAR

- 35 kHz ultraljudsteknik

- Ultraljudsverktyg och förseglingsmedel i en enhet

- Komplett system för integration i fyllningslinjer

- Kontinuerligt styrsystem för vibratorstruktur och städ

- Plan-parallellt system av sonotrode och städ

- Förseglingsstyrka justerbar mellan 50 – 430 N

- Störande konturer över verktygsnivå (inte i förseglingsområdet)

- Fast stopp som tillval

TEKNISKA DATA

| Max. förseglingsbredd [mm] | 90 |

| Max. slaglängd [mm] | 2 x 30 |

| Max. stängningskraft [N] | 430 |

| Antal cykler [cykler/min] vid max. slaglängd | 12 |

| Max. lufttryck [bar] | 6 |

| Räckvidd på städsidan [mm] | 164 |

| Räckvidd på sonotrode-sidan [mm] vid 35 kHz | 456 |

| Mått på förseglingstång B x H x D [mm] | 90 x 240 x 620 |

Med reservation för ändringar.

Ultraljudsförseglingssystem för slangformiga påsar

Det nya ultraljudsförseglingssystemet för vertikala (VFFS) och horisontella (HFFS) slangformiga påsar är en innovation inom förpackningsteknik. Systemet levererar helt täta svetssömmar och är extremt material- och energieffektiv.

De kalla verktygen trycker ihop den slangformade påsen för försegling. Sonotrodernas ultraljudsoscillationer gör sedan att molekylkedjorna i förseglingsområdet bryts upp med värmebildning och nya fogar bildas. På mycket kort tid produceras förseglingssömmar av utmärkt kvalitet.

Produktionsfel minskar drastiskt med hjälp av ultraljud, eftersom själva innehållet inte värms upp. Innehållet som finns i tätningsområdet separeras också av ultraljudseffekten under förseglingsprocessen. Kvaliteten på den producerade sömmen och påsfilmens barriärskikt påverkas inte.

FÖRDELAR:

- Konsekventa förseglingsresultat av enastående kvalitet

- Ingen förvrängning av tätningarna (hot-tack)

- Expanderbara sömbredder tack vare modulära sonotrodsystem

- Minskad filmförbrukning

- Smala tätningssömmar (ner till < 1 mm möjligt)

- Tät försegling av mycket tunna filmer, även när de kommer i kontakt med innehållet

- Ingen förstörelse av barriärskikt

- Betydligt färre produktionsfel

- Minskade underhållskostnader

- Kan användas i vertikala (VFFS) och horisontella (HFFS) slangformiga påsmaskiner

Ultraljudsförseglingssystemet för slangformiga påsar har använts framgångsrikt i flera år med vår partner GEA Food Solutions i VFFS-maskiner.

Ultraljudssystem för blisterförpackningar, brickor, tråg och koppar

Med det patenterade, modulära sonotrodbordet kan blisterförpackningar, brickor, tråg eller koppar förseglas och stansas i ett steg. Detta gör att efterföljande stansmaskiner inte behövs och förpackningsprocessen blir kortare.

FÖRPACKNING SOM INTE ÄR BEROENDE AV FORMAT

Eftersom sonotroderna, som avger ultraljudet, är placerade i ett plant svetsområde kan sonotrodbordet användas oavsett format. Det räcker med att helt enkelt byta städplatta eller mottagningsverktyg för att ändra förpackningsformatet. Detta resulterar i stor flexibilitet i förpackningsdesignen.

FÖRDELAR:

- Modulärt system

- Fri formatering

- Kombinerad försegling och stansning

- Rena, icke-vassa stansade kanter

- Snabba verktygsbyten

- Lång verktygslivslängd

- Förseglings- och stanskvalitet som kan valideras

FÖRPACKNINGAR SOM ÄR BEROENDE AV FORMAT

För formatberoende förpackningslösningar med ultraljud anpassar vi inte bara mottagningsverktygen till det förpackade godset utan även själva sonotroderna. Beroende på användningsområde kombineras även tätnings- och stansningsuppgifter i detta fall.

FÖRDELAR:

- Formatberoende, anpassade och applikationsspecifika verktyg

- Stor erfarenhet av verktygskonstruktion

- Egen verktygstillverkning

Med reservation för ändringar.

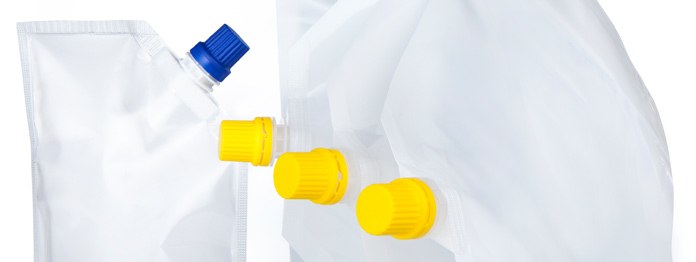

Ultraljudsförseglingssystem för påsar

Ultraljudssystemen används bland annat för att försegla prefabricerade, ståpåsar och plana påsar.

Varierande specialformat är inte bara förseglade utan även stansade eller storleksskurna med ultraljud. Dragkedjor eller ventiler kan också byggas in samtidigt.

Den största fördelen med ultraljud jämfört med andra tekniker är att påsarna kan förslutas helt tätt även när förseglingsområdet är i kontakt med innehållet. Mekanisk förpressning av kallförseglingsverktygen och den efterföljande ultraljudseffekten tvingar ut innehållet ur tätningsområdet. Produktens smak ändras inte.

FÖRDELAR:

- Täta sömmar även i försglingsområden som är i kontakt med produkten

- Smaken på innehållet påverkas inte

- Applikationsanpassade system

Med reservation för ändringar.

Ultraljudssvetssystem för kartonger

Ultraljudssvetssystemen SONOTRONIC är lämpliga för kartonger som är belagda med en svetsbar yta.

Kartonger belagda med en förseglingsbar yta är lämpliga för ultraljudsbearbetning. När det gäller dryckeskartonger är denna beläggning vanligtvis gjord av PE. Ultraljud används för att försegla förslutningarna, som också är gjorda av PE, ordentligt mot kartongens tätningsskikt.

En annan tillämpning av kartong i emballagesvetsar med blisterbrickor. Skiktet på kartongen måste anpassas till blistermaterialet. De genomskinliga blisterförpackningarna, som vanligtvis är termoformade av PET, gör att produkten kan visas optimalt, medan den svetsade kartongen används för att förmedla produktinformation.

Fördelar

- Kalla svetskomponenter i titan

- Inga lim eller tillsatser

- Svetsning av matchade förpackningsmaterial

- PE-lock på PE-belagda kartonger

- PET-blisterförpackningar på PET-belagda kartonger

- Ekonomiskt, ekologiskt och resursbesparande

Samtidig ultraljudsskärning och försegling

Skär- och förseglingsprocess med ultraljud används överallt där det är viktigt att försegla kanterna när de skärs eller för att göra processen effektivare genom att kombinera de två stegen och undvika efterföljande stansning.

Ultraljudsprocessen Cut&Seal används överallt, där det är viktigt att försegla kanter när de skärs eller för att göra en process mer effektiv genom att kombinera de två stegen och undvika efterföljande stansning. Till exempel inom förpackningsindustrin används sonotrod-bordet, med vilket blister, brickor eller koppar kan förseglas och stansas ut i ett steg.

Cut&Seal används inom textilindustrin vid svetsning av elastiska och icke-elastiska termoplastiska textilier kontinuerligt med hjälp av rullsömsmodulen eller intermittent med upprättstående sonotroder. Den största fördelen med ultraljud Cut&Seal är att kanterna redan är förseglade under skärningen, vilket förhindrar efterföljande fransning.

FÖRDELAR:

- Kombinerad svetsning och skärning eller försegling och stansning av

- Filmer och förpackningar, även om de är förorenade i förseglingszonen.

- Elastiska och icke-elastiska syntetiska textilier

- Snabba och reducerade processtider med god processäkerhet

- Sammanfogning och trimning av flera lager i en process

- Ingen efterföljande stansutrustning behövs

- Reproducerbar svets- och stanskvalitet

- Fullständig övervakning av processparametrarna under produktionen

- Flexibel svetsdesign

- Minsta svetsutsprång

- Stanskanter som inte är vassa och är solida och fria från ludd

- Miljövänlig teknik

- Lågt energibehov och därmed snabbare cykeltider

- Inga lösningsmedel och tillsatser krävs för svetsning

- Typspecifik återvinning av svetsade arbetsstycken

Ultraljudsskärning av livsmedel

Oavsett om det gäller stora industriella bagerier, i konfekttillverkning eller osttillverkning – vår ultraljudsskärteknik är mångsidig i olika applikationer.

Ultraljud lämpar sig speciellt väl för skärning av spröda, mjuka eller krämiga produkter. Tack vare ultraljudstekniken uppstår ingen deformering av produkten. Således kan även mycket tunna skivor kan kapas. Ultraljudet ger upphov till minimal ytfriktionen och säkerställer rena snitt utan att produkten fastnar på skärverktyget, eller i minimal utsträckning.

Bageriprodukter som innehåller grädde eller sockerhaltiga lager, såväl som andra deg- eller fetthaltiga livsmedel, kan skäras eller trimmas på ett kontrollerat sätt med ultraljud för att producera en kvalitet som är visuellt tilltalande. Skärgeometrierna för verktygen för längsgående snitt eller tvärsnitt är individuellt anpassade till produktkraven.

Som ett resultat av ultraljudsvibrationer förblir endast små produktrester vidhäftade vid sonotroden, så att den i viss utsträckning visar en självrengörande verkan.

På grund av ultraljudsvibrationerna arbetar skärande sonotroder med ett lägre initialtryck än konventionella fräsar. Samtidigt är slitaget på sonotroden mindre och skärkvaliteten är betydligt bättre. Dessutom har användningen av ultraljudsskärningssystem en positiv effekt på utrustningens underhålls- och stilleståndstider.

Fördelar:

- Behaglig skär- och formstabilitet

- Produktspecifika skärgeometrier

- Skärning med sonotroder har liten produktvidhäftning och en självrengörande verkan

- Minskning av underhålls- och stilleståndstider

- Produkterna skärs nästan oavsett konsistens

Med reservation för ändringar.