CAT-teknik

TIGRES CAT-teknik

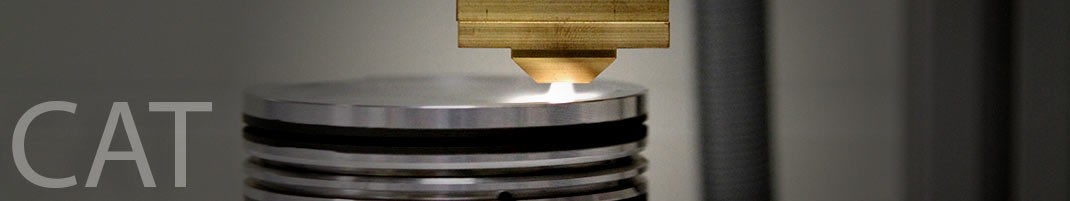

Praktiskt taget potentialfri plasma med hög effektiv räckvidd

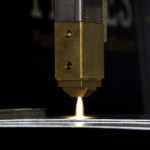

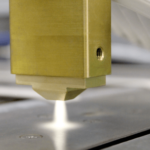

Atmosfärisk plasma används för effektiv rengöring och ultrafin rengöring samt för aktivering av ytor av metall, plast, glas och kompositer. Behandlingen säkerställer korrekt vidhäftning under den efterföljande lim-, tryck- eller lackeringsprocessen.

Översikt

Med CAT-teknik genereras potentialfri plasma av två ljusbågar, varvid motbågen också fungerar som motelektrod. Denna metod minimerar effekterna av slitage av plasmagenerering. Oavsett om du använder ett enda munstycke för en bearbetningsbredd på 20 – 40 mm per huvud eller använder flera munstycken som är uppradade tillsammans för bredare applikationer – denna kraftfulla teknik erbjuder en lösning som passar alla energikrävande förbehandlingar. En generator kan försörja upp till två munstyckshuvuden. Särskilda funktionella grupper kan appliceras på polymerytan med olika processgaser även i detta fall.

Tekniska data Plasma CAT

| Effekt: | 600 W eller 1000 W per munstycke |

| Kanaler: | 1-4 |

| Processgas: | Luft (annat på begäran) |

| Potential-fri: | Praktiskt taget |

| Transformer: | Extern |

Energy Discharge Control (EDC) kan användas

Skalbarhet

Tekniken kan anpassas till valfri materialbredd genom att variera antalet huvuden. Beroende på processparametrarna har plasmabehandlingen ett effektivt intervall på 5 – 30 mm.

Processintegration

Matningsledningarna till Plasma CAT-huvudena kan löpa parallellt eller vinkelrätt mot munstycket.

Viktiga egenskaper hos CAT-tekniken

- Generatorn producerar potentialfri plasma, som förs med en luftström ut ur elektroden och ut på ytan som ska behandlas.

- Effekt CAT Compact 600 W, effekt CAT 1 kW

- Ett eller två huvuden av olika serier kan monteras på en generator

- Drift med gas och gasblandningar möjlig

- Försörjningsledningarna finns i längderna 2 m, 4 m och 8 m

- Konstant övervakning av systemets driftstatus säkerställer processtillförlitlighet