Applikationer

CO2 Snow Jet Cleaning

Applications

The acp CO2 Snow-Jet Cleaning process is usefull for manual or for fully automated cleaning and activating of nearly any materials like plastics, glas, ceramics, metals, semiconductors, etc.

Applications are cleaning /activating of e.g. ceramic substrates, transparent plastic surfaces for car front lights before coating, glas surfaces, semiconductor surfaces, surfaces in electronics, plastic surfaces before coating or glueing processes.

|

|

|

Degreasing and removal of lubricants

|

|

|

De-oiling a fine metal membrane

before cleaning with CO2 snow-jet technique

|

De-oiling a fine metal membrane

after cleaning with CO2 snow-jet technique

|

Deflashing and Cleaning of a precision component

|

|

Cleaning plastic components before painting

Alternatives to the established power-wash process are increasingly being searched for to clean plastic parts such as fenders, door sills or industrial components before painting.

With the acp CO2 snow-jet technique, a cleaning process that may be a part of an automated flow process has been developed which is capable of removing typical contamination such as internal and external separating agents, fingerprints, production dust, etc., without leaving any residues.

Investment and operating costs are much lower than those associated with the power-wash process. Special nozzle arrays are used to achieve typical painting cycle times.

Use of nozzle arrays with the CO2-Snow Jet Cleaning

|

|

Laser Processing

Today, the use of lasers in material processing is state of the art. A reproducible, clean and oil-free surface is essential in order to safeguard process stability, e.g. when laser welding. The acp technique can be automated in-line directly prior to the laser process and is thus ideally suited for cleaning such surfaces.With common laser processes such as laser cutting or engraving, so-called smoke residue is formedwhich impairs both the optical and technical properties of a component.

Smoke residue is removed rapidly and reliably using the CO2 snow-jet cleaning technique. Furthermore, by pre-cleaning surfaces with CO2 snow, the formation of smoke residue can be considerably reduced.

.

.

.

.

|

|

| Laser welding, before cleaning with the CO2 snow-jet technique | Laser welding, after cleaning with the CO2 snow-jet technique |

|

|

|

Laser engraving, before cleaning with the CO2 snow-jet technique

|

Laser engraving, after cleaning with the CO2 snow-jet technique

|

Removal of Fine burrs

Burrs are often formed when precision components are machined or when plastic parts are manufactured using injection-molding processes. The turbulent CO2 cleaning jet can be implemented as an automated process to rapidly remove tiny burrs.

|

|

|

Component before burr removal using CO2 snow-jet technique

|

Component after burr removal using CO2 snow-jet technique

|

Cleaning of Sensitive and Finely Structured Surface

The CO2 Snow-Jet process is not abrasive and can therefore be utilized for cleaning sensitive and finely-structured surfaces.

In plastics processing, the cleaning of molds or forms is a fundamental task.

The mobile cleaning system JetWorker enables the form to be cleaned in-built, thus enabling stoppage times to be considerably reduced. The simple handling of the device permits uncomplicated and rapid cleaning between the individual processing steps.

In this way, the service life of molds can be distinctly improved. In the same uncomplicated way, residue from cleaning agents can be quickly and gently removed.

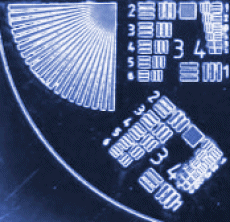

Cleaning of Bond Pads in Electronic Manufacturing

Very high demands are placed on the reliability of bond pads. However, certain demands are also placed on the cleaning of bond pads as far as the selection of a suitable cleaning method is concerned.Locally-defined areas need to be cleaned selectively; at the same time, adjacent subsystems may not be damaged.With a minimum jet dot diameter of currently 3 mm, the CO2 Snow-Jet process is able to do this. The process can also be automated and is dry, thus avoiding the need for expensive drying processes.

|

|

|

|

Cleaning welding flux from bond pads before CO2

|

Cleaning welding flux from bond pads after CO2

|

CO2-Snow Jet Cleaning in photovoltaics

|

|

|

Solar cell before cleaning with the CO2 snow-jet technique

|

Solar cell after cleaning with the CO2 snow-jet technique

|

Cleaning of Adhesive Sites

|

In order to improve the quality of adhesive bonding, adhesive sites are cleaned before the bonding process. Joint adhesive tests between acp – advanced clean production GmbH and Loctite GmbH have shown that the adhesive properties of surfaces which have been cleaned using the CO2 Snow-Jet process are improved by a significant amount in comparison with cleaning using typical solvents.

Even in the case of plastics such as polyethylene which are especially difficult to adhere, a marked improvement in adhering characteristics could be measured. Cleaning with CO2 Snow-Jet Cleaning systems is fast, uncomplicated and can be automated. |

Reinigen von optischen Komponenten mit CO2 Schnee

|

|

Nichtabrasive Reinigung von beschichteten Metallspiegeln für Hochleistungs-CO2-Laser. Verschmutzung: Fingerabdruck (40x).